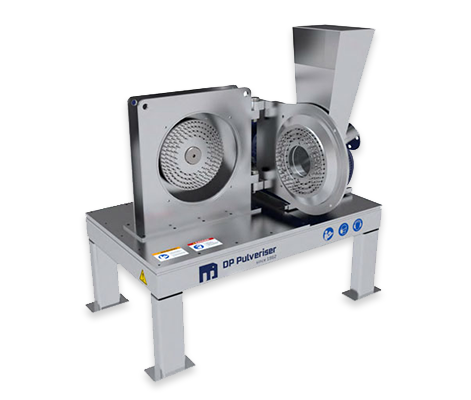

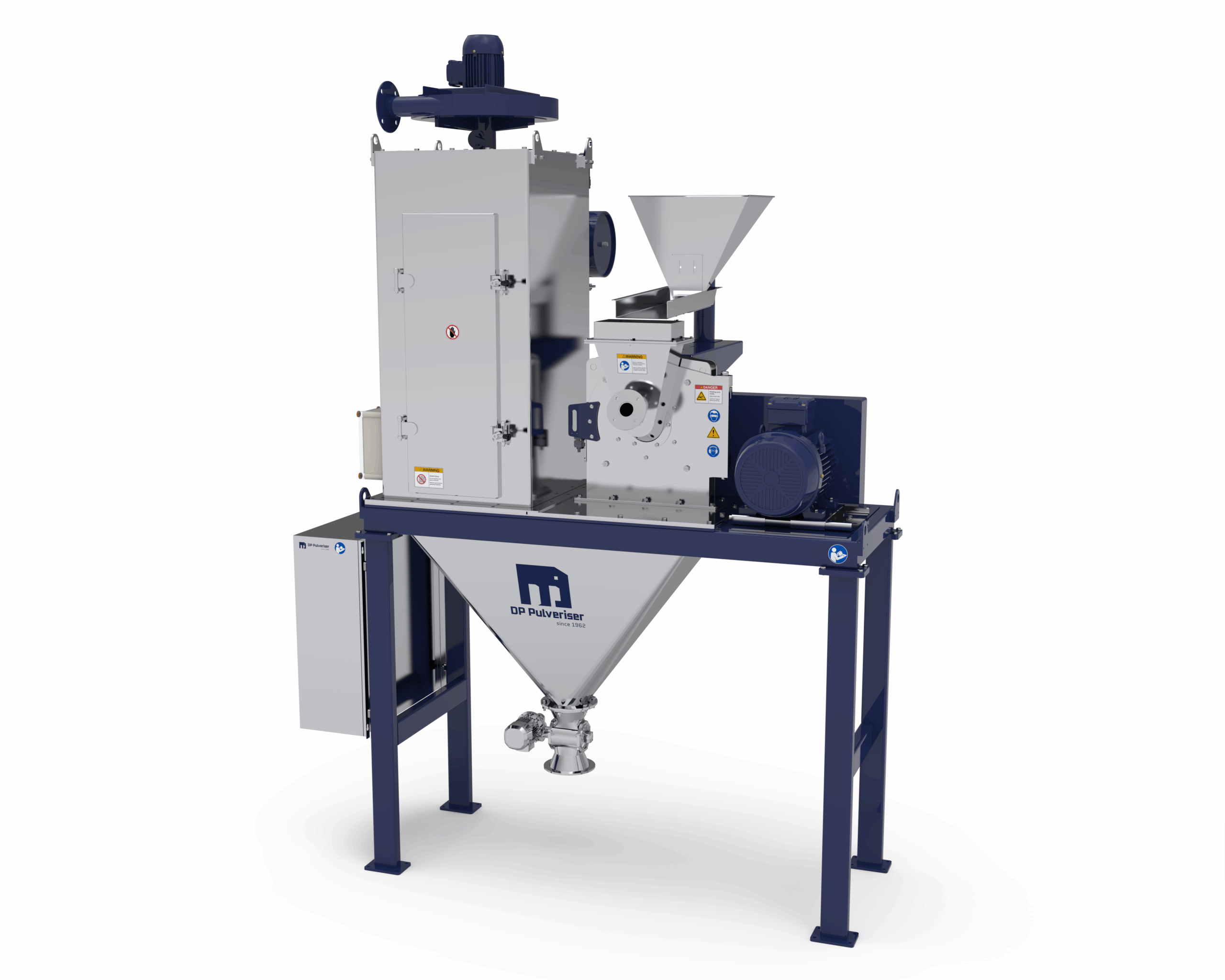

Processing metallic powders, ores, minerals, and ceramic compounds demands more than just basic equipment—it requires robust construction, precise particle control, and the ability to handle abrasive and high-density materials without excessive wear or contamination.

At DP Pulverizer, we specialize in milling systems designed to process hard, abrasive, dense, and chemically active materials with precision. Whether you’re grinding metal oxides, ceramic powders, carbonates, or recycled alloys, our solutions deliver repeatable particle size, minimal wear, and scalable throughput from lab to production.

Engineering solutions that fuel client success.

Hardox, tungsten carbide, ceramic, or stainless steel internals available.

Tailored solutions for sub-10 µm to 2,000 µm particle ranges.

Built to withstand silica, alumina, titanium dioxide, and metallic dusts.

Optional nitrogen or argon integration for reactive metal powders.

Modular systems ready for raw material prep or final micronization.