In today’s fast-evolving food and beverage industry, manufacturers require powder processing solutions that are not only efficient and reliable—but also sanitary, scalable, and tailored to ingredient performance.

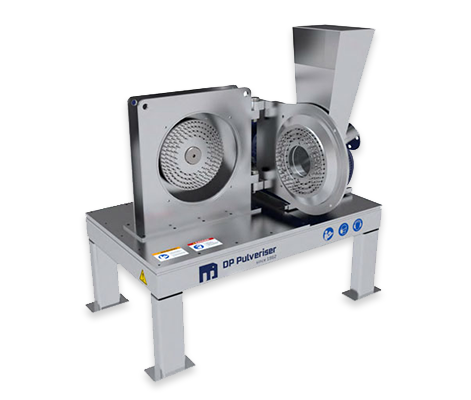

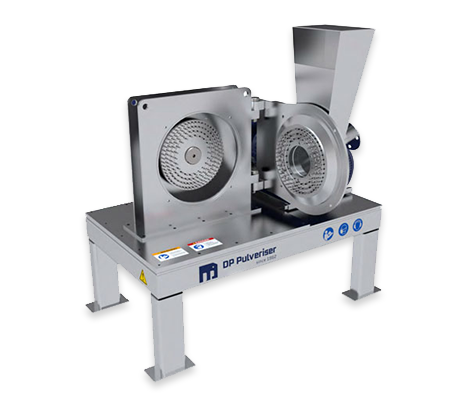

At DP Pulverizer, we provide food-grade milling systems designed to grind, micronize, and classify powders across the food processing spectrum. Whether you produce spices, flavors, flours, proteins, sweeteners, starches, or extracts, our technology ensures consistent particle size, maximum flavor retention, and compliance with global food safety standards.

Engineering solutions that fuel client success.

Stainless steel construction, CIP (clean-in-place) ready, and easy access for washdown or manual cleaning.

Modular designs accommodate startups, co-packers, and large-scale facilities.

Cryogenic and low-heat mills prevent degradation during processing.

From bulk bag filling to inline packaging, designed to integrate with your process flow.