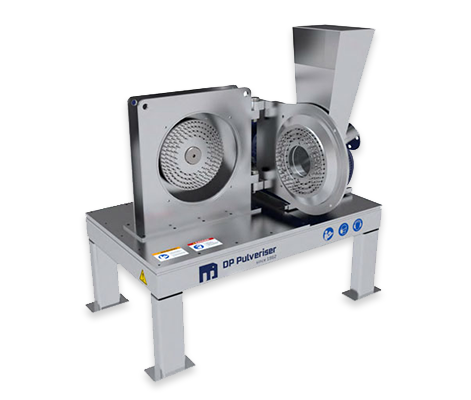

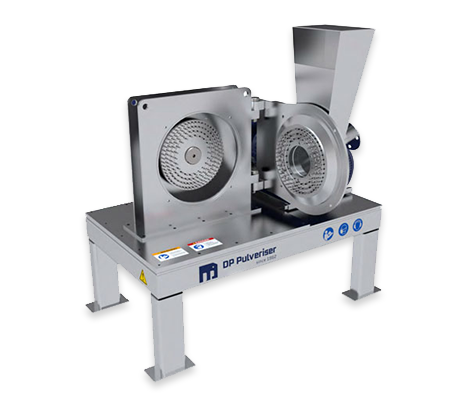

Agricultural processing requires robust, high-throughput milling equipment that can handle everything from raw biomass and grains to fertilizers, plant fibers, and soil enhancers. At DP Pulverizer, we offer a full line of industrial milling systems engineered for durability, flexibility, and efficiency—backed by materials and designs ready to withstand the demands of the ag industry.

From animal feedstock and crop residue to organic fertilizers, biochar, and value-added plant-based powders, DP Pulverizer ensures precision size reduction with consistent results.

Engineering solutions that fuel client success.

Optional wear-resistant liners (e.g., Hardox), robust steel frames, and easy maintenance.

Capable of continuous operation in high-volume environments.

Handles soft to fibrous materials, from seeds to dried roots to grain husks.

Modular systems available in lab, pilot, and production sizes.