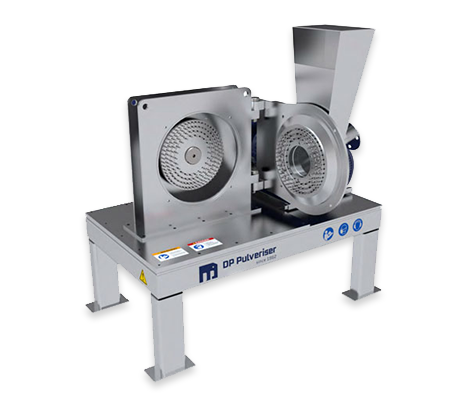

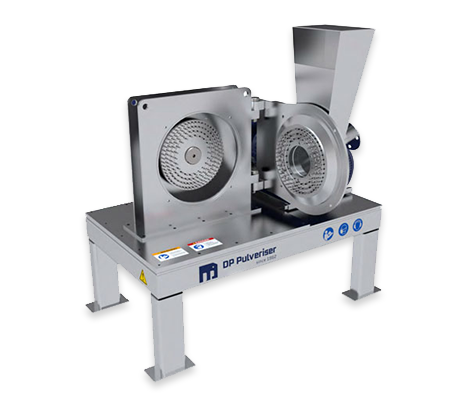

The nutraceutical industry is growing rapidly—and so is the demand for high-quality, bioavailable, and clean-label powders. At DP Pulverizer, we specialize in milling technologies that meet the strict performance, hygiene, and flexibility requirements of nutraceutical manufacturers.

Whether you’re producing herbal extracts, plant-based proteins, vitamins, minerals, or functional superfoods, our broad portfolio of mills ensures particle size precision, material integrity, and batch consistency—from lab-scale to high-capacity production.

Engineering solutions that fuel client success.

Stainless steel contact parts, contamination-free grinding, and optional inert gas handling.

Cryogenic and low-heat milling technologies protect bioactives, enzymes, and oils.

Designed to handle fibrous, resinous, or elastic plant materials.

From startup production to contract manufacturing and global exports.