Engineering solutions that fuel client success.

Achieve uniform coating thickness and smooth finishes with controlled D50 and D90 targets.

Available with wear-resistant or ceramic internals to prevent metal contamination.

Essential for thermally sensitive powders and pigment dispersion.

Seamless separation of oversized particles to ensure consistent coating quality.

Ideal for toll processors, powder manufacturers, and R&D coating labs.

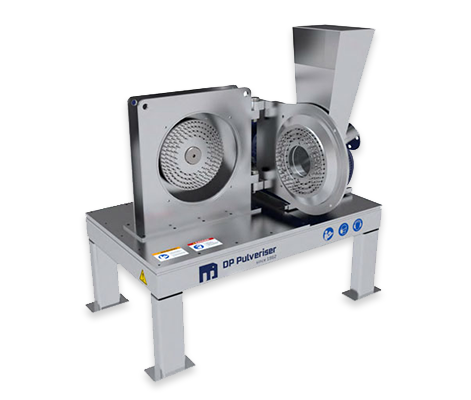

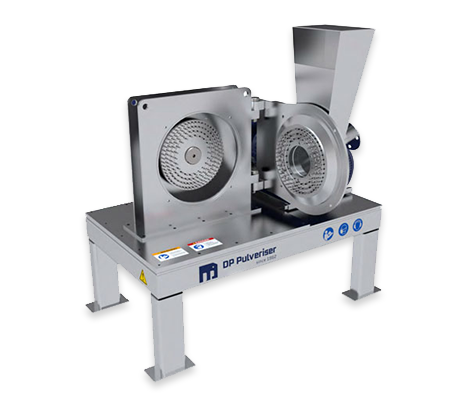

• Combines high-speed impact milling with integral dynamic classification

• Produces smooth, consistent powder for electrostatic spraying

• Adjustable classifier speed for on-the-fly PSD tuning

• No mechanical contact during grinding = zero contamination

• Ideal for high-end or functional coatings

• Available with ceramic liners and inert gas options

• Reliable and compact design for efficient throughput

• Great for processing base resins or pigment masterbatches

• Easy to clean and maintain

• Interchangeable rotor options for impact, shear, or turbo-style milling

• One system to handle multiple coating formulations

• Easy changeover between product lines

• Liquid nitrogen keeps material brittle during grinding

• Prevents thermal softening, pigment bleed, or smearing

• Improves color retention and dispersion in the final blend