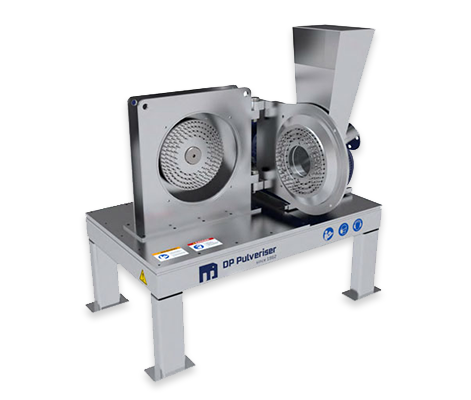

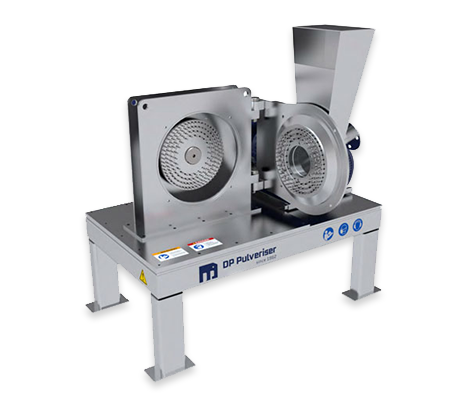

At DP Pulverizer, we understand that pharmaceutical manufacturers require more than just equipment—they require precision, compliance, cleanliness, and consistency. Our complete line of pharmaceutical milling solutions is engineered to meet the highest standards of GMP, FDA, and cleanroom compatibility, delivering unmatched particle size control, batch reproducibility, and operational efficiency.

From API micronization to excipients, natural extracts, polymers, and formulation powders, our technologies help you scale from R&D to production with confidence.

Engineering solutions that fuel client success.

Stainless steel (SS304/SS316L) construction, mirror-polished internals, tool-free access, and clean-in-place (CIP) or easy manual cleaning options.

From coarse granulation to ultra-fine micronization (<1 µm), we deliver targeted results with minimal loss.

Our solutions prevent thermal degradation and preserve molecular integrity.

From bench-scale development to high-volume continuous production.