In the race toward electrification and clean energy, precision powder processing is non-negotiable. Battery and energy manufacturers require ultra-consistent particle size, strict contamination control, and often inert gas environments for handling reactive or sensitive materials.

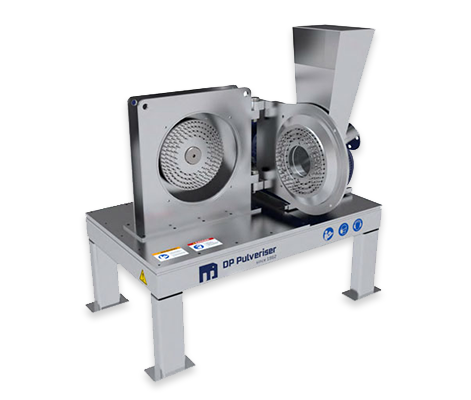

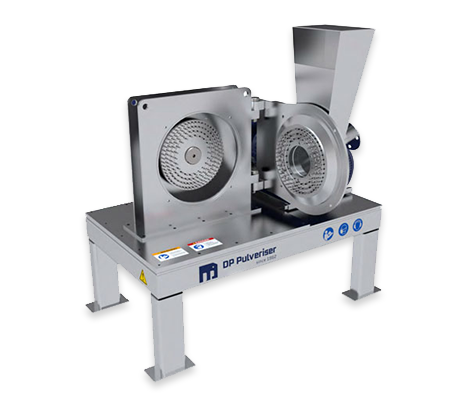

At DP Pulverizer, we deliver advanced milling technologies that meet the exacting standards of the battery, supercapacitor, hydrogen storage, and conductive additive industries. Whether you’re producing cathode/anode materials, solid electrolytes, or carbon-based conductive powders, our mills are engineered for performance, safety, and scale.

Engineering solutions that fuel client success.

Achieve narrow particle size distributions (D50 from 1–100 µm) to optimize conductivity and reactivity.

Ceramic, tungsten carbide, and stainless-steel contact surfaces available.

Jet mills, air classifier mills, and cryogenic mills with N₂ or Ar for oxidation-sensitive materials.

Safe systems for fine metal powders, carbon black, and other volatile materials.

Modular platforms for R&D labs, pilot plants, and full-scale battery manufacturing lines.