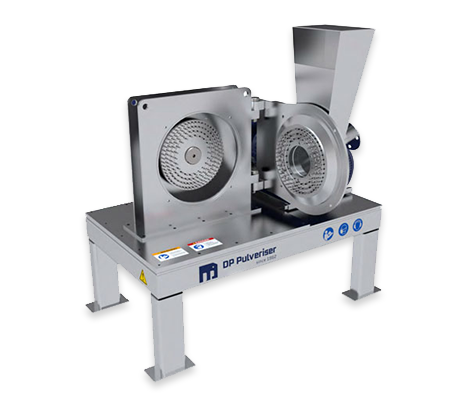

DP Pulverizer Universal Mills offer flexible, multi-mode grinding with interchangeable tools—ideal for diverse materials, frequent changeovers, and fine to coarse powder processing.

Universal mills are ideal for companies producing a variety of materials or changing SKUs frequently

Need help selecting the right solution? Contact us now

A universal mill is a highly versatile grinding system designed to accommodate multiple types of milling technologies—impact, attrition, and turbo milling—within a single housing. It allows for interchangeable grinding elements and adjustable rotor speeds, enabling a wide range of particle sizes, material types, and production goals.

DP Pulverizer Universal Mills are built for flexibility, durability, and precision, making them the go-to choice for processors working with diverse product lines or requiring frequent material changeovers.

Universal mills operate by using rotor-driven grinding tools, such as pins, hammers, or turbines, to reduce particle size through impact or attrition. Key features include:

At DP Pulverizer, our universal mills are built with modular design, long-lasting components, and adaptability in mind.

Whether you’re a co-packer working with hundreds of SKUs, a pharma manufacturer needing multi-material capability, or a specialty chemical processor—our universal mills provide a future-proof grinding solution.

Engineering solutions that fuel client success.