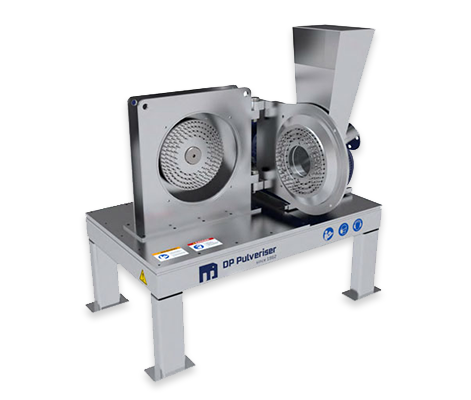

DP Pulverizer Pin Mills offer high-speed, impact-based grinding for fine to medium powders—ideal for efficient, consistent processing across food, pharma, chemical, and battery industries.

DP Pulverizer Pin Mills are used across a wide variety of industries:

Need help selecting the right solution? Contact us now

A pin mill is a type of impact mill that grinds materials through repeated collisions with finely spaced pins mounted on a rotating disc. Unlike traditional mills, pin mills provide high-speed impact-based size reduction that is both efficient and consistent, making them ideal for a wide range of fine to medium grinding applications.

At DP Pulverizer, we manufacture robust, versatile pin mills designed to deliver uniform particle sizes with high throughput and minimal downtime.

Pin mills operate on a rotor-stator principle, using concentric discs studded with pins to break down materials:

At DP Pulverizer, our pin mills are designed to offer reliability, precision, and versatility. Whether you need a small batch mill for R&D or a high-capacity system for industrial production, our machines are engineered to perform in the toughest conditions.

With customizable pin configurations, multiple material options (SS304, SS316, Hastelloy, etc.), and inert gas compatibility, our pin mills are built to exceed expectations.

Engineering solutions that fuel client success.